NEW YORK CITY SUBWAY SYSTEM

New York City Subway System

A Historical Outlook on its Construction

New York City was the second-largest city in the world in the advent of the 20th century, with the majority of its 3.4 million people living in Manhattan and much fewer people living in Brooklyn, Staten Island, and Queens. Public transportation of the time-electric omnibus, gasoline powered trolleys and elevated railways-was inadequate for getting people where they needed to go quickly and efficiently. It could take hours just to get from Wall Street to Harlem in the days when Greenwich Village was considered a suburb.

The idea of an underground subway system had been discussed by politicians for decades, and finally it was decided in 1900 that a subway would be built. Interborough Rapid Transit Company (IRT) won the job after its bid of $35 million was accepted.

The job consisted of building 21 miles of tunnels and 58 miles of tracks. Of that, 46 ½ miles were to be built underground and 11 ½ miles were to be elevated. Additionally, there were to be 43 local stations, five express stations and ten station elevators. All this was expected to be completed in only four and a half years. The contractor also agreed that he was responsible for any damage done to existing buildings and traffic would not be affected by construction.

Construction Begins on Historic Subway

Ground was broken in March 1900 in Manhattan. The construction company chose shallow cut and cover as the excavation method to avoid having to tunnel deep under New York's infrastructure. Wooden planking and bridges covered the construction so that traffic could continue over the tunneling that would go on for years.

Five different types of construction were used in building the subway: flat roof and I-beams for the roof and sides, supported by steel bulb-angle columns was used on 52% of the roads; reinforced concrete roof was used on Lennox Avenue and in Battery Park; concrete lined tunnel on 23% of the road; elevated road on steel viaduct was used on 24% of the road; and cast-iron tubes were used under the Harlem and East Rivers.

The construction that was typical for the majority of the project was a flat roof I-beam construction with a concrete bottom. The side walls had I-beam columns five feet apart, with vertical concrete arches between the columns. The I-beams supported the masonry, allowing the walls to be built thinner than they could have been if concrete alone was used. The tops of the wall columns were connected by roof beams, supported by rows of steel columns between the tracks. They were built on concrete and cut stone bases. Because the tunnels were susceptible to water damage from the ground, several inches of felt washed with hot asphalt were laid behind the walls, over the roof and under the floor. In some places, this method of waterproofing was reinforced with one or two courses of brick. Terra cotta ducts for the electric cables were placed between the steel columns and waterproofing.

The construction that was typical for the majority of the project was a flat roof I-beam construction with a concrete bottom. The side walls had I-beam columns five feet apart, with vertical concrete arches between the columns. The I-beams supported the masonry, allowing the walls to be built thinner than they could have been if concrete alone was used. The tops of the wall columns were connected by roof beams, supported by rows of steel columns between the tracks. They were built on concrete and cut stone bases. Because the tunnels were susceptible to water damage from the ground, several inches of felt washed with hot asphalt were laid behind the walls, over the roof and under the floor. In some places, this method of waterproofing was reinforced with one or two courses of brick. Terra cotta ducts for the electric cables were placed between the steel columns and waterproofing.

The station on 42nd Street between Park Avenue and Madison Avenue required a special method of construction. Five subway tracks passed through this area, and the excavation reached a depth of 35 feet and extended 15 feet into the rock. In order to construct this segment of the subway, a 30-foot wide trench had to be sunk on the south side of the street, in which the subway was built for the width of two tracks. At 50-foot intervals tunnels had to be driven toward the north side of the street, with tops four feet above the roof of the subway and bottoms on the roof. The ends of the tunnels were connected by a parallel tunnel just beyond the line of the fourth track. Workers were then able to excavate the rock in the bottom of the tunnels to their final depth. A bed of concrete was then placed in the parallel tunnel, and a third row of steel columns was erected in order to support the concrete and steel roof.

In order to complete the tunnel for a width of four tracks, the construction company excavated the earth between the tunnels, with poling boards and struts supporting the material above. In this way, workers were able to extend the roof of the subway sideways over the rock below. The rock beneath was excavated when the roof was finished. The fifth track was completed by tunneling to the limits of the subway and blasting out the rock below.

The contractors decided that using reinforced concrete instead of steel roof beams in certain places would work better. The rods were 1 ¼ inches square, and laid out from six to ten inches apart, depending on the roof loads in the different places. Layers of concrete were then laid over the rods so that the rods were imbedded. The same procedure was used on the sides of these tunnels as well.

The work was very difficult in many places because of the sewers, water and gas mains, steam pipes and electrical conduits. Work was particularly difficult where the tunnels passed close to the foundations of large buildings and other structures. For example, the subway passed directly under the Hotel Belmont at 42nd Street and Park Avenue. Construction workers had to use extra heavy steel girders and foundations in order to support both the hotel and the subway station there.

Monument Creates Unique Construction Challenge

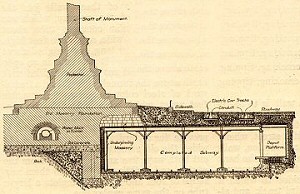

Another similar challenge was posed by the 75-foot tall, 700-ton Columbus Monument near the southwest entrance of Central Park. The subway would pass under the east side of the monument within three feet of its center, reducing a significant portion of the monument's support. In order to ensure the safety of the monument and the workers, a tunnel six feet wide and seven feet high was dug under the monument just outside the subway's wall line. Works put in a concrete bottom in order to support a row of wooden posts that would carry the footing above. When this was done, the tunnel was filled with masonry rubble, making a wall that was strong enough to support the monument during the subway's construction.

Another similar challenge was posed by the 75-foot tall, 700-ton Columbus Monument near the southwest entrance of Central Park. The subway would pass under the east side of the monument within three feet of its center, reducing a significant portion of the monument's support. In order to ensure the safety of the monument and the workers, a tunnel six feet wide and seven feet high was dug under the monument just outside the subway's wall line. Works put in a concrete bottom in order to support a row of wooden posts that would carry the footing above. When this was done, the tunnel was filled with masonry rubble, making a wall that was strong enough to support the monument during the subway's construction.

Problems arose not just from buildings above ground, but also from those below ground. At 42nd Street and Broadway, the pressroom of the new New York Times building was actually below the subway. The subway was built literally through the building, with the building's columns passing through a subway station. Workers used steel channels to brace the very tall building and ensure that it was not damaged.

Construction workers built the subway close to the surface in many places, and because of this many underground pipes and ducts had to be moved and reconstructed. For example, at the 66th Street station the roof of the subway was a mere two feet from the electric railway yokes and structures of the street surface line. Workers had to remove two large gas mains, build troughs between the subway roof beams and substitute in five smaller gas mains, all without interrupting the mains' use.

In the course of building the subway, the construction company created the second longest double-track rock tunnel in the United States. It runs from under Park Avenue to Lenox Avenue. Along the tunnel from 116th Street to 120th Street resides one of the widest concrete arches in the world, 37.5 feet wide. The two-track subway was created by tunneling through micaceous rock and removing top headings, all done from two shafts and one portal. Using percussion drills, the blasting of the headings was done by an eight-hour night shift. The spoils were removed in the morning and used to make the concrete that lined the tunnel.

Workers encountered trouble during the construction of the section on Park Avenue from 34th Street to 41st Street. The rock in this area was very slippery and on a steep incline. Although every precaution was taken, the surface above the east tunnel was disturbed and several houses were damaged. Workers used Portland cement grout to strengthen the affected area of the work space so that no further damage was done.

The contractors agreed that building the tubes that run under the Harlem River was the most interesting and exciting part of this project. The War Department required that the river have a minimum depth of 20 feet at low tide, so that set the elevation of the roof of the submerged part of the track. The track ran 1500 feet, including the approaches, and was lined in concrete. Workers had to tunnel under water through a bed of mud, silt and sand. Much of this material was so fluid that it had to be removed with a jet. Excavation of the tunnel went down 50 feet.

Because the War Department required that half of the river must always stay open, only one half of the tunnel could be built at a time. Workers dredged a trench over the tunnel line 50 feet wide, 39 feet below low water. They then drove three rows of piles on each side of the trench from the west bank to the middle of the river and built working platforms on them. Piles were driven over the area where the subway was to be built, over which a trussed framework was floated and sunk.

The roof was constructed of three courses of 12-inch timbers separated by 2-inch planks. This was also floated over the piles and sunk. When it was put into place, it was covered with earth and excavation could begin. Both air and water pressure were used to excavate. When excavation was complete, the piles were braced so that the concrete and cast-iron lining could be put into place. The piles were then cut off as the concrete bed was laid. The second half of the tunnel was constructed in a similar manner.

World's Largest Subway System Completed

The subway system was completed and opened for business on October 27, 1904. The price to ride was a nickel and 150,000 stood in line to take a ride on the first subway train. New Yorkers applauded IRT's innovations, especially its use of electric power which added nothing to the city's air pollution. With a four-track design that could run in each direction at both local and express speeds, IRT had built the fastest public transportation system in the world. Its slogan: "City Hall to Harlem in 15 minutes!"

The subway system was completed and opened for business on October 27, 1904. The price to ride was a nickel and 150,000 stood in line to take a ride on the first subway train. New Yorkers applauded IRT's innovations, especially its use of electric power which added nothing to the city's air pollution. With a four-track design that could run in each direction at both local and express speeds, IRT had built the fastest public transportation system in the world. Its slogan: "City Hall to Harlem in 15 minutes!"

Neighborhoods sprung up around the planned subway stations and the population grew. In 1900 few people lived in Brooklyn, but by 1914 it was home to one million people. On Monday, December 23, 1946, 8,872,244 people rode the New York subway system, a record that still stands today.

Thanks to IRT, New York City flourished and developed into the city it is today because the subways enabled people to live in one area of the large city and work in another, with quick and efficient travel in between.

Since the subway was built, over 100 stations have been renovated, with many more planned. More than 1,000 new cars have been put into use, at a price of $2.4 billion - more than it cost to build the entire subway system itself. But renovations were not done by IRT. The company went bankrupt during the Depression and the city took it over.