HOOVER DAM

Hoover Dam

A Historical Outlook on its Construction

A list of modern day construction projects that demonstrate a construction company's ingenuity and creativity may very well begin with The Hoover Dam.

A list of modern day construction projects that demonstrate a construction company's ingenuity and creativity may very well begin with The Hoover Dam.

The Hoover Dam was built by a construction company called Six Companies Inc, which was actually a consortium of several companies: Morrison-Knudsen Co., Utah Construction Co., J. F. Shea Co., Pacific Bridge Co., MacDonald & Kahn Ltd. and a joint venture of W. A. Bechtel Co., Henry J. Kaiser, and Warren Brothers. The reason these construction companies got together was simple: no single construction company could raise the $5 million needed to secure the performance bond.

A number of construction companies were interested in the job. After all, this was a historical project of great significance, as well as an incredible challenge. It soon became obvious, though, that no one company would be able to handle a project of this magnitude. Even the very biggest construction companies in that day had neither the capital nor the resources to take on such a job.

Harry Morrison, president of Morrison-Knudson Co., approached San Francisco banker Leland Cutler to seek financial backing for Morrison-Knudsen Co. for the Hoover Dam project. Cutler refused because he didn't think any one company could raise the $5 million bond that was necessary, but he did give Morrison the names of several other construction companies who might be interested in a joint venture. Morrison quickly realized the only way to get the Hoover Dam built was for several companies to join together, and he organized the Six Companies consortium.

At that time, the leading dam builder in the United States was Frank T. Crowe, a former Department of Reclamation superintendent. Crowe had spent twenty years working for the Department of Reclamation, as well as private construction companies. He had helped to build Arrowrock Dam in Idaho, the Jackson Lake Dam in Wyoming and Washington's Tieton Dam. Crowe had also developed a cableway system of delivering concrete and moving equipment that was far more advanced than any other system of its time.

Everything Crowe had ever done during his career helped prepare him for the building of Hoover Dam, which would be the biggest challenge of his life. Crowe aided Reclamation Commissioner Arthur Powell Davis in developing a cost estimate for a dam on the lower Colorado River as early as 1919 and also helped with the preliminary design in 1924.

Prior to 1925, when the Reclamation Service (which later became the Department of Reclamation) wanted to build a dam, the government did the project itself. In 1925, the government began contracting such projects out. Frank Crowe wanted very badly to work on the Hoover Dam; in fact, it had been a dream of his for a very long time. And now that the Reclamation Service had changed its way of doing business, Crowe had to choose between staying in his government job or working on the Hoover Dam. To work on off the Hoover Dam project, Crowe would be forced to leave his job and team up with a construction company. Crowe decided to join Morrison-Knudsen Co., and was instrumental in persuading Morrison to organize Six Companies.

Since Crowe had two decades of experience and had worked on the project's cost estimate for the government, he knew what went into the calculations the government used to develop their estimates. Morrison gathered together the construction companies that would make up Six Companies, made Crowe construction superintendent and won the contract on March 4, 1931. Six Companies bid $48.9 million for the project, a bid that was just $24,000 higher than the Department of the Interior had budgeted for the project and $10 million lower than the next lowest bid. At the time, this was the largest single contract the United States government had ever awarded. In today's dollars, that bid would be more than $577 million.

Six Companies Delivered Comprensive Construction Expertise

Each member of the Six Companies consortium brought a special expertise to the table. The Wattis Brothers of Utah Construction were well known for their expertise in building the early railroads in the western United States and Mexico. The JF Shea Company had started out as a plumbing business and was experienced in tunnel building and other underground work. Charles Shea knew people at the Pacific Bridge Company, and he convinced them to bring their expertise and capital to the project. Felix Kahn of San Francisco's MacDonald and Kahn had built a number of large buildings in San Francisco and contributed $1 million to the project. Henry Kaiser and Warren Bechtel were experienced in road building.

Each member of the Six Companies consortium brought a special expertise to the table. The Wattis Brothers of Utah Construction were well known for their expertise in building the early railroads in the western United States and Mexico. The JF Shea Company had started out as a plumbing business and was experienced in tunnel building and other underground work. Charles Shea knew people at the Pacific Bridge Company, and he convinced them to bring their expertise and capital to the project. Felix Kahn of San Francisco's MacDonald and Kahn had built a number of large buildings in San Francisco and contributed $1 million to the project. Henry Kaiser and Warren Bechtel were experienced in road building.

Word of the Hoover Dam project spread quickly, and Six Companies quickly received more than 2,400 job applications and over 12,000 letters of inquiry about jobs. This was during the Depression. Times were tough and many people desperately needed work. Workers flocked to the building area from all over country, more than 5,000 in all. Many brought their wives and children and lived in tents. With poor sanitation, little access to clean water, 119-degree heat and no utilities, this tent community was a living hell. Six Companies realized that these people would be here for years and something had to change. Along with the Reclamation Service and under Frank Crowe's guidance, Six Companies built Boulder City. Electricity was brought in, and a school, churches, post office, library, newspaper and stores were built.

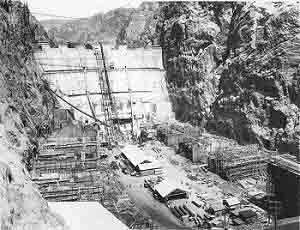

Before construction on the dam could start, a monumental task was at hand. The construction companies had to divert the Colorado River away from the project's foundation site, and this could only happen during the winter. Crowe decided this needed to be done during the winter of 1932-33. Work on the tunnels began in May 1931. For 24 hours a day, seven days a week four tunnels, two on each side, were built right through the rock walls of the canyon. Each tunnel was 4,000 feet long, 56 feet in diameter, and lined with three feet of concrete, making them the second largest tunnels ever made.

The diversionary tunnels had to be built in the summer in order to be ready to divert the river in the winter. Conditions in the tunnels were brutal, with temperatures inside reaching 140 degrees Fahrenheit. As many as four workers died from heat prostration each week. To make matters worse, Six Companies used gasoline-powered trucks in the tunnel, something that had never been done before in underground mining, so carbon monoxide was added to the heat, dust, and fumes from the blasting.

Crowe was a mechanical genius, something he had proven time and time again on his previous dam projects. He conceived of many new inventions during the course of building Hoover Dam, one of which occurred during the building of the diversionary tunnels. He came up with a drilling jumbo, four platforms welded to a truck that carried 30 rock drills. This enabled construction workers to complete the tunnels and cofferdams by April 1932, a full year ahead of schedule. Construction on the dam base could now begin.

In order for Six Companies to recover its initial $5 million investment, it gave high prices for the work done in the diversion phase and lower prices for subsequent work. But in order for this to work, Frank Crowe had to place the 3.4 million cubic yards of concrete necessary to complete the dam for only $2.70 per yard, a price that was 35% lower than the price of the second lowest bidder. Further, Six Companies had agreed to a $3,000 per day penalty for every day the project went over schedule, so it was imperative that everything go according to plan. Crowe overcame these challenges magnificently. Not only was he able to get the concrete into place at the right price, he also did it ahead of schedule.

In order for Six Companies to recover its initial $5 million investment, it gave high prices for the work done in the diversion phase and lower prices for subsequent work. But in order for this to work, Frank Crowe had to place the 3.4 million cubic yards of concrete necessary to complete the dam for only $2.70 per yard, a price that was 35% lower than the price of the second lowest bidder. Further, Six Companies had agreed to a $3,000 per day penalty for every day the project went over schedule, so it was imperative that everything go according to plan. Crowe overcame these challenges magnificently. Not only was he able to get the concrete into place at the right price, he also did it ahead of schedule.

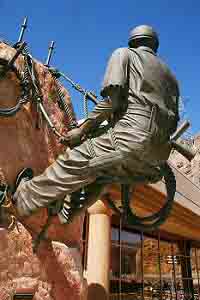

The base of the Hoover Dam, as with any dam, was the most important part of the structure. If the base wasn't built correctly, to there could be numerous potential problems with the rest of the structure. Construction workers had to use power shovels to dig through more than half-million cubic yards of river bottom mud to reach the bedrock 40 feet below, making the total excavation 125 feet, with grouting as deep as 150 feet. Simultaneously, high scalers blasted the canyon walls with jackhammers to make a smooth surface for the dam's construction. These scalers earned $5.60 a day and were some of the highest paid workers on the job.

On June 6, 1933, two years after Six Companies won the contract, they started pouring the concrete for the dam's base. In order to allow the concrete to dry properly and not crack during the process, construction workers had to pour 230 individual blocks of concrete for the base. All in all, 3.25 million cubic yards of concrete were used for the base, enough concrete to pave a highway 16 feet wide from New York to San Francisco.

The first eight-cubic-yard bottom-dump bucket of concrete went into the dam 18 months ahead of schedule. The dam's great mass of concrete was stripped of heat by pumping refrigerated water through 590 miles of pipe placed in the concrete as it was poured. The four 395-foot intake towers were taller than most buildings. The powerhouse's two 230-foot-high wings were designed to house 17 generating units. When construction was complete in 1935, the diversionary tunnels were closed, and the filling of Lake Mead began.

The Construction Project Completed

All in all, Hoover Dam stood 725 feet high, is 1244 feet wide, 660 feet thick at the base, tapering to a thickness of 45 feet at the top. It cost a total of $165 million to build and was completed in four and a half years. The project was begun in March 1931 and President Franklin D. Roosevelt dedicated it on September 30, 1935. First power was produced in October 1936, more than two years ahead of schedule. A total of 4.4 million yards of concrete were used in its construction. The powerhouse used 17 generators in 10 acres of floor space to produce over 4 billion kilowatt-hours for California, Nevada, and Arizona.

All in all, Hoover Dam stood 725 feet high, is 1244 feet wide, 660 feet thick at the base, tapering to a thickness of 45 feet at the top. It cost a total of $165 million to build and was completed in four and a half years. The project was begun in March 1931 and President Franklin D. Roosevelt dedicated it on September 30, 1935. First power was produced in October 1936, more than two years ahead of schedule. A total of 4.4 million yards of concrete were used in its construction. The powerhouse used 17 generators in 10 acres of floor space to produce over 4 billion kilowatt-hours for California, Nevada, and Arizona.

The name of the dam has changed several times. Early in the construction process, surveyors thought the dam should be built at Boulder Canyon because of its granite floor, and the dam was to be called Boulder Dam. It was later determined that Black Canyon was a more suitable site since a dam in this location would not have to be quite as high, but the name was left as Boulder Dam. During the strike-driving ceremony on September 17, 1930, Secretary of the Interior Ray L. Wilbur named the dam Hoover Dam in honor of President Herbert Hoover, which came as a great surprise to everyone. In 1933 voters elected Democrat Franklin D. Roosevelt as president, and his Secretary of the Interior Harold Ickes changed the name back to Boulder Dam. Fourteen years later, a joint resolution of Congress changed the name back to Hoover Dam.

Six Companies accomplished a historic feat, working together to build the Hoover Dam. The construction companies that made up the consortium went their separate ways after the Hoover Dam project, and accomplished a variety of successful projects afterwards.

Morrison-Knudsen Company president Henry Morrison appeared on the cover ofTime Magazine in 1954, his company having grown to one of the largest construction and engineering companies in the world. The company was involved with many construction projects, including the Trans-Alaska pipeline. Morrison died in 1971. In 1996 Morrison-Knudesen Company was acquired by Washington Group International.

The Utah Construction Company diversified into commercial, residential and military construction, as well as mining, in the 1950s. The company changed its name in 1971 to Utah International, Inc. and entered into a $2.3 billion merger with General Electric in 1976.

J.F. Shea helped to build the Grand Coulee Dam, the Golden Gate Bridge, the San Francisco Bay Area Rapid Transit system and the Washington, D.C., subway system. The company is still in business today. It builds planned communities and is a civil engineering, electrical and construction contractor, as well as a supplier of aggregate materials to contractors. The company also manufactures concrete-placing equipment for civil engineering projects.

The Pacific Bridge Company went back to building bridges, including the Tacoma Narrows Bridges. The company also worked with Morrison-Knudsen Company on the salvage project after the bombing of Pearl Harbor.

Bechtel has completed more than 22,000 projects in 140 countries, including the Channel Tunnel, Hong Kong International Airport, the San Francisco Bay Area Rapid Transit (BART) system and the reconstruction of Kuwait's oil fields after the Gulf War.

Henry Kaiser worked on the Grand Coulee Dam and the San Francisco Bay Bridge. In 1939 he founded Permanente, the largest cement plant in the world and joined with Todd Shipbuilding Co. to build ships for the Merchant Marines.

Warren Brothers Paving, who had built the first modern asphalt facility in 1901 went on to pave the Columbia River highway and worked on the Walden Pond demonstration project.

And what happened to Frank Crowe, the superintendent for the Hoover Dam project? He made a $350,000 bonus at the completion of the Hoover Dam. After that he went on to build four more dams in his life, but no other project would match the scale and impact of the Hoover Dam.